Unraveling the Power of Flexibility and Convenience

Unlocking the mystery of cat trolley cables can seem like a daunting task, but with this comprehensive guide, you’ll be well on your way to understanding the intricacies of these essential electrical components. From their humble beginnings to their modern applications, cat trolley cables have come a long way in revolutionizing the way we connect and harness electrical power. In this article, we’ll delve into the world of cat trolley cables, exploring their definition, history, key components, functionality, and benefits, as well as their applications in various industries.

As we navigate the complexities of electrical installations, it’s crucial to understand the role of cat trolley cables in providing flexible and movable electrical connections. Whether you’re an electrician, engineer, or simply curious about the inner workings of electrical systems, this guide will provide you with a deep understanding of cat trolley cables and their significance in modern electrical installations.

So, let’s embark on this journey to unlock the secrets of cat trolley cables and discover how they’re shaping the future of electrical connections. From their conductor materials to their trolley system operation, we’ll explore every aspect of these remarkable cables and uncover their potential for growth and innovation.

1. What are Cat Trolley Cables?

Cat trolley cables are a type of electrical cable designed to provide a flexible and movable electrical connection for lighting, power, and control systems. These cables are commonly used in industrial and commercial settings, such as factories, warehouses, and construction sites, where equipment and machinery need to be frequently moved or repositioned. The term ‘cat trolley’ refers to the cable’s ability to move along a track or conduit, allowing for easy repositioning of equipment and minimizing the risk of damage or disconnection.

At its core, a cat trolley cable consists of a insulated conductor, typically made of copper or aluminum, surrounded by a protective jacket and supported by a trolley system. The trolley system, which includes a track or conduit, allows the cable to move smoothly along its length, providing a reliable and efficient electrical connection. This unique design enables cat trolley cables to withstand the rigors of industrial and commercial environments, where equipment and machinery are subject to frequent movement and vibration.

In electrical installations, cat trolley cables play a crucial role in providing power and control to equipment and machinery. They are often used in conjunction with other electrical components, such as motors, switches, and sensors, to create a comprehensive electrical system. By understanding the basics of cat trolley cables, electrical engineers and technicians can design and implement efficient and reliable electrical systems that meet the demands of industrial and commercial applications.

Definition and Purpose

A cat trolley cable is a type of electrical cable that provides a flexible and movable electrical connection for lighting, power, and control systems. This unique design allows the cable to move along a track or conduit, providing a reliable and efficient electrical connection. The flexible nature of cat trolley cables makes them ideal for applications where equipment and machinery need to be frequently moved or repositioned.

The primary purpose of cat trolley cables is to provide a movable electrical connection that can withstand the rigors of industrial and commercial environments. They are designed to be durable and resistant to damage, with a protective jacket and insulation that protects the conductor from damage and electrical shock. This makes them an essential component in many industrial and commercial applications, including factories, warehouses, and construction sites.

In addition to their flexibility and durability, cat trolley cables are also designed to be easy to install and maintain. They are often used in conjunction with other electrical components, such as motors, switches, and sensors, to create a comprehensive electrical system. By providing a flexible and movable electrical connection, cat trolley cables enable the efficient and reliable operation of equipment and machinery, making them a critical component in many industries.

History of Cat Trolley Cables

The history of cat trolley cables dates back to the early 20th century, when the need for flexible and movable electrical connections in industrial and commercial settings became apparent. The first cat trolley cables were developed in the 1920s, primarily for use in factories and warehouses, where equipment and machinery needed to be frequently moved or repositioned. These early cables were simple in design, featuring a copper or aluminum conductor surrounded by a rubber or fabric insulation.

Over the years, the design and materials used in cat trolley cables have evolved significantly. In the 1950s and 1960s, the development of new materials and technologies led to the creation of more durable and flexible cables. The introduction of plastic insulation and jackets in the 1970s and 1980s further improved the performance and reliability of cat trolley cables. Today, cat trolley cables are a staple in modern electrical installations, used in a wide range of applications, from industrial manufacturing to commercial construction.

The widespread adoption of cat trolley cables can be attributed to their ability to provide a reliable and efficient electrical connection in a variety of environments. They have become an essential component in many industries, including manufacturing, construction, and transportation. As technology continues to evolve, cat trolley cables are likely to remain a crucial element in the development of modern electrical systems, enabling the efficient and reliable operation of equipment and machinery.

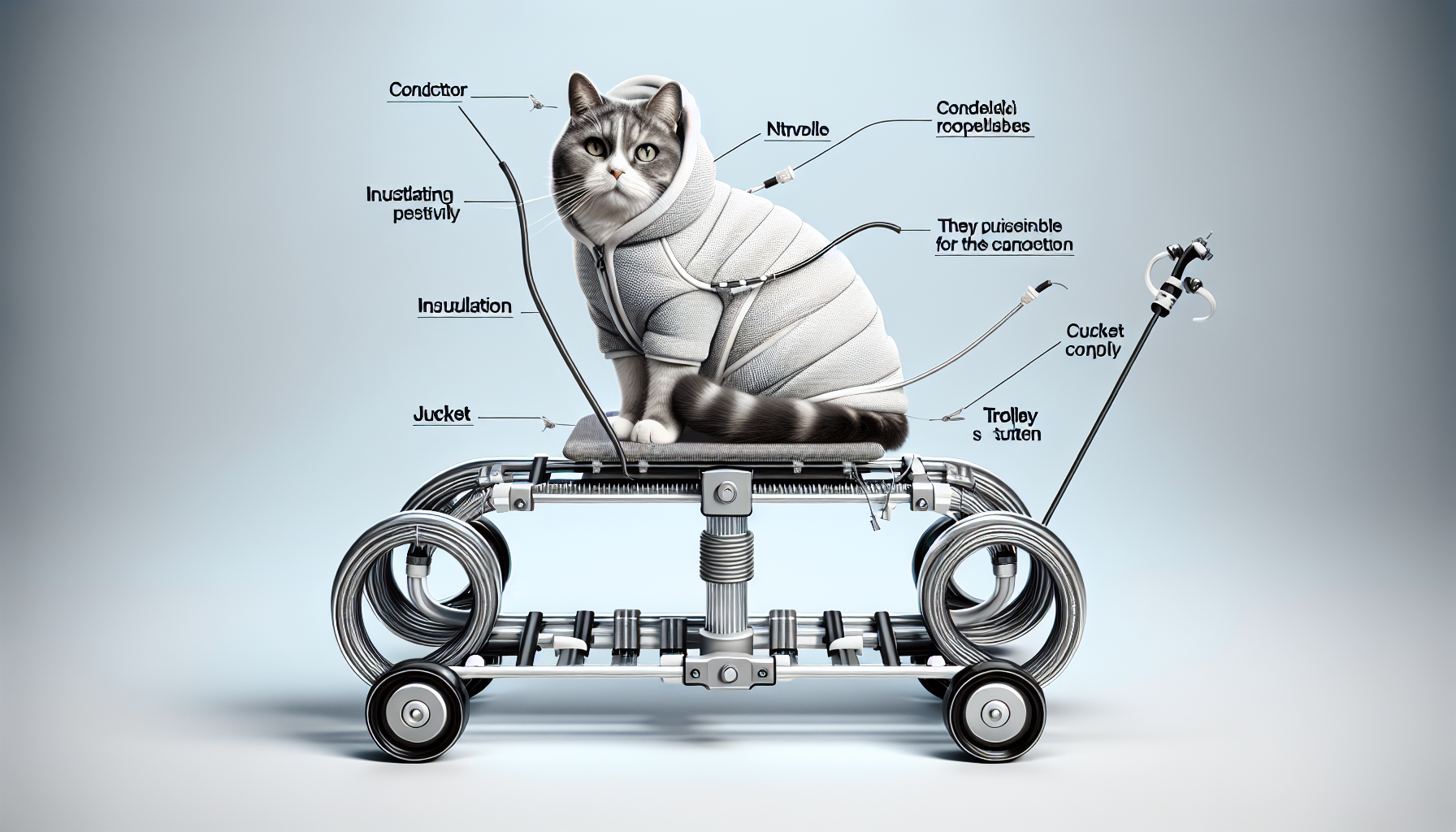

2. Key Components of Cat Trolley Cables

A cat trolley cable is comprised of several key components that work together to provide a flexible and movable electrical connection. At the core of the cable is the conductor, typically made of copper or aluminum, which carries the electrical current. The conductor is surrounded by a layer of insulation, which protects the conductor from electrical shock and prevents damage to the cable.

The insulation is typically made of a durable material, such as rubber or plastic, and is designed to withstand the rigors of industrial and commercial environments. The insulation is then surrounded by a jacket, which provides additional protection to the cable and prevents damage from abrasion, moisture, and other environmental factors. The jacket is often made of a flexible material, such as PVC or rubber, which allows the cable to move smoothly along the track or conduit.

In addition to the conductor, insulation, and jacket, cat trolley cables also feature a trolley system, which allows the cable to move along the track or conduit. The trolley system consists of a series of pulleys and guides that support the cable and enable it to move smoothly and efficiently. By combining these key components, cat trolley cables provide a reliable and efficient electrical connection that can withstand the demands of industrial and commercial applications.

Conductor Materials

The conductor material is a critical component of cat trolley cables, responsible for carrying electrical current efficiently and safely. Two of the most commonly used conductor materials in cat trolley cables are copper and aluminum. Copper conductors are known for their high conductivity, flexibility, and durability, making them an ideal choice for applications where high current carrying capacity is required. Aluminum conductors, on the other hand, are lighter and more cost-effective, but still offer good conductivity and corrosion resistance.

The choice of conductor material depends on the specific application and requirements of the cat trolley cable. Copper conductors are often used in high-power applications, such as industrial machinery and lighting systems, where high current carrying capacity is essential. Aluminum conductors, on the other hand, are commonly used in lower-power applications, such as control systems and signaling devices, where weight and cost are a consideration.

In addition to their electrical properties, the conductor material also affects the overall durability and reliability of the cat trolley cable. Both copper and aluminum conductors are designed to withstand the rigors of industrial and commercial environments, including exposure to moisture, vibration, and extreme temperatures. By selecting the right conductor material for the application, cat trolley cables can provide a reliable and efficient electrical connection, ensuring the smooth operation of equipment and machinery.

Insulation and Jacketing

Insulation and jacketing are critical components of cat trolley cables, providing protection to the conductor and ensuring the reliability and safety of the electrical connection. The type of insulation and jacketing material used in cat trolley cables depends on the specific application and environment in which the cable will be used. Common insulation materials include thermoplastic materials such as PVC and PE, as well as thermoset materials such as rubber and epoxy.

The choice of insulation material is influenced by factors such as temperature rating, moisture resistance, and abrasion resistance. For example, PVC insulation is commonly used in cat trolley cables for general-purpose applications, while rubber insulation is often used in cables that require high flexibility and resistance to moisture and abrasion. Epoxy insulation, on the other hand, is used in high-temperature applications where the cable is exposed to extreme heat.

Jacketing materials, which provide additional protection to the insulation and conductor, are also critical to the performance of cat trolley cables. Common jacketing materials include PVC, PE, and nylon, which offer varying degrees of flexibility, abrasion resistance, and chemical resistance. By selecting the right insulation and jacketing materials, cat trolley cables can provide a reliable and safe electrical connection, even in the most demanding environments.

3. How Do Cat Trolley Cables Function?

Cat trolley cables are designed to provide a flexible and movable electrical connection, enabling smooth and efficient power transmission in a variety of industrial and commercial applications. The cable’s unique design and functionality allow it to move along a track or conduit, while maintaining a reliable and safe electrical connection. This is achieved through the cable’s conductor configuration, which consists of a series of insulated conductors surrounded by a protective jacket and supported by a trolley system.

The conductor configuration is designed to ensure efficient power transmission, while also providing flexibility and durability. The insulated conductors are arranged in a specific pattern to minimize electromagnetic interference and ensure reliable signal transmission. The protective jacket and trolley system work together to support the cable and enable smooth movement along the track or conduit. This allows the cable to withstand the rigors of industrial and commercial environments, including exposure to vibration, moisture, and extreme temperatures.

The result is a flexible and reliable electrical connection that can be easily moved and repositioned as needed. This makes cat trolley cables an ideal solution for applications where equipment and machinery need to be frequently moved or repositioned, such as in manufacturing, construction, and warehousing. By understanding the mechanics of cat trolley cables, users can design and implement efficient and reliable electrical systems that meet the demands of their specific application.

Conductor Configuration

The conductor configuration is a critical component of cat trolley cables, as it determines the cable’s ability to efficiently transmit power and data. The conductors are arranged in a specific pattern to minimize electromagnetic interference, ensure reliable signal transmission, and provide flexibility and durability. Typically, the conductors are arranged in a multi-conductor configuration, where multiple insulated conductors are twisted together to form a single cable.

The conductor arrangement is designed to balance the electrical and mechanical properties of the cable. For example, the conductors may be arranged in a circular or rectangular configuration to minimize electromagnetic interference and ensure efficient power transmission. The insulation and jacketing materials used to protect the conductors also play a crucial role in determining the cable’s overall performance.

The conductor configuration is also influenced by the specific application and environment in which the cable will be used. For example, cables used in high-temperature applications may require specialized conductor materials and arrangements to ensure reliable performance. By understanding the conductor configuration, users can design and implement efficient and reliable electrical systems that meet the demands of their specific application. Whether it’s in manufacturing, construction, or warehousing, cat trolley cables with optimized conductor configurations can provide a reliable and efficient electrical connection.

Trolley System Operation

The trolley system is a critical component of cat trolley cables, enabling smooth movement and connection in a variety of industrial and commercial applications. The trolley system consists of a track or conduit, along which the cable is free to move, and a series of pulleys and guides that support and direct the cable’s movement. This allows the cable to move freely along the track, while maintaining a reliable and secure electrical connection.

The trolley system operates by using a series of rollers or bearings to support the cable’s movement, minimizing friction and ensuring smooth operation. The pulleys and guides are designed to keep the cable aligned and properly positioned, preventing twisting or kinking that could compromise the electrical connection. This ensures that the cable can move freely and efficiently, even in complex or confined spaces.

The trolley system is designed to be flexible and adaptable, allowing it to be used in a wide range of applications and environments. Whether it’s in manufacturing, construction, or warehousing, the trolley system enables cat trolley cables to provide a reliable and efficient electrical connection, even in the most demanding conditions. By understanding the mechanics of the trolley system, users can design and implement efficient and reliable electrical systems that meet the demands of their specific application.

4. Benefits and Applications of Cat Trolley Cables

Cat trolley cables offer a range of benefits and applications that make them an essential component in various industries and settings. One of the primary advantages of cat trolley cables is their flexibility and convenience, allowing for easy movement and repositioning of equipment and machinery. This makes them ideal for applications where equipment needs to be frequently moved or rearranged, such as in manufacturing, construction, and warehousing.

In addition to their flexibility, cat trolley cables also offer a high level of safety and reliability, making them suitable for use in harsh environments. They are designed to withstand exposure to vibration, moisture, and extreme temperatures, ensuring that the electrical connection remains secure and reliable. This makes them an essential component in industries such as mining, oil and gas, and aerospace, where equipment and machinery are subject to extreme conditions.

The benefits and applications of cat trolley cables are numerous and varied, and they are used in a wide range of industries and settings. From manufacturing and construction to warehousing and material handling, cat trolley cables provide a reliable and efficient electrical connection that enables equipment and machinery to operate at peak performance. By understanding the benefits and applications of cat trolley cables, users can design and implement efficient and reliable electrical systems that meet the demands of their specific application.

Flexibility and Convenience

Cat trolley cables are designed to provide flexibility and convenience in industrial and commercial applications, making them an essential component in many industries. One of the primary ways they achieve this is by allowing for easy movement and repositioning of equipment and machinery. This is particularly useful in applications where equipment needs to be frequently moved or rearranged, such as in manufacturing, construction, and warehousing.

The flexibility of cat trolley cables also enables them to be used in confined or hard-to-reach spaces, where traditional electrical connections may be impractical or impossible. This makes them ideal for use in applications such as overhead cranes, conveyor systems, and automated machinery. Additionally, the convenience of cat trolley cables lies in their ability to minimize downtime and reduce the risk of damage or disconnection. This is especially important in industries where equipment downtime can result in significant losses in productivity and revenue.

The flexibility and convenience of cat trolley cables are also enhanced by their durable design and construction. They are built to withstand the rigors of industrial and commercial use, including exposure to vibration, moisture, and extreme temperatures. This makes them a reliable and efficient solution for providing electrical power and control in a wide range of applications. By understanding the benefits of cat trolley cables, users can design and implement efficient and reliable electrical systems that meet the demands of their specific application.

Safety and Reliability

Cat trolley cables are designed to provide a high level of safety and reliability in harsh environments, making them an essential component in industries where equipment and machinery are subject to extreme conditions. One of the primary safety features of cat trolley cables is their ability to withstand exposure to vibration, moisture, and extreme temperatures. This is achieved through the use of durable materials and robust construction, which ensures that the electrical connection remains secure and reliable.

In addition to their durability, cat trolley cables also feature a range of safety features that reduce the risk of electrical shock, fire, and other hazards. These include insulation and jacketing materials that are resistant to abrasion and moisture, as well as built-in fault protection and overcurrent protection. This ensures that the electrical connection is safe and reliable, even in environments where equipment and machinery are subject to extreme stress and vibration.

The reliability of cat trolley cables is also enhanced by their ability to withstand the rigors of industrial and commercial use. They are designed to operate in environments where equipment and machinery are subject to frequent movement, vibration, and impact, and are built to last for extended periods of time. This makes them a reliable and efficient solution for providing electrical power and control in a wide range of harsh environments, from manufacturing and construction to mining and oil and gas.

5. Conclusion: The Importance of Cat Trolley Cables

In conclusion, cat trolley cables play a vital role in modern electrical installations, providing a flexible and reliable electrical connection for a wide range of applications. From industrial and commercial settings to manufacturing and construction, cat trolley cables have proven themselves to be a crucial component in ensuring the smooth operation of equipment and machinery. Their ability to withstand harsh environments, combined with their durability and safety features, make them an essential component in many industries.

As the demand for efficient and reliable electrical systems continues to grow, the importance of cat trolley cables will only continue to increase. With advancements in technology and materials, cat trolley cables are poised to become even more efficient, reliable, and adaptable, making them an essential component in the future of electrical connections. As industries continue to evolve and adapt to new challenges, the significance of cat trolley cables will only continue to grow, making them a vital component in the development of modern electrical installations.

In summary, cat trolley cables are a crucial component in modern electrical installations, providing a flexible and reliable electrical connection for a wide range of applications. Their durability, safety features, and ability to withstand harsh environments make them an essential component in many industries, and their potential for future growth is vast. As the demand for efficient and reliable electrical systems continues to grow, the importance of cat trolley cables will only continue to increase, making them a vital component in the future of electrical connections.

Industry Trends and Future Developments

The cat trolley cable industry is constantly evolving, with new technological advancements and innovations being developed to meet the demands of an increasingly complex and interconnected world. One of the latest trends in cat trolley cable technology is the development of hybrid cables, which combine the benefits of traditional cat trolley cables with the flexibility and reliability of newer materials. These hybrid cables are designed to provide improved performance, increased durability, and enhanced safety features, making them an attractive option for industries such as manufacturing, construction, and oil and gas.

Another trend in cat trolley cable technology is the integration of smart sensors and IoT devices, which enable real-time monitoring and control of electrical systems. This allows for improved efficiency, reduced downtime, and enhanced safety, as well as the ability to remotely monitor and diagnose issues. Additionally, the development of new materials and insulation technologies is enabling the creation of cat trolley cables that are lighter, more flexible, and more durable, making them ideal for use in harsh environments and confined spaces.

As the industry continues to evolve, it is likely that we will see even more innovative developments in cat trolley cable technology. The potential impact of these developments on the industry is significant, with improved performance, increased efficiency, and enhanced safety features all contributing to a more reliable and efficient electrical system. As the demand for efficient and reliable electrical systems continues to grow, the cat trolley cable industry is poised to play a critical role in shaping the future of electrical connections.

Final Thoughts

As we conclude our exploration of cat trolley cables, it is clear that these humble components play a vital role in the functioning of modern electrical systems. From industrial and commercial settings to manufacturing and construction, cat trolley cables are an essential component in ensuring the smooth operation of equipment and machinery. Their ability to provide a flexible and reliable electrical connection, combined with their durability and safety features, make them an indispensable component in many industries.

As the demand for efficient and reliable electrical systems continues to grow, the importance of cat trolley cables will only continue to increase. Their role in shaping the future of electrical connections is critical, as they provide a flexible and adaptable solution for a wide range of applications. Whether it’s in the development of new technologies, the improvement of existing systems, or the creation of innovative solutions, cat trolley cables are poised to play a central role in the evolution of electrical connections.

In reflection, it is clear that cat trolley cables are more than just a simple component – they are a vital link in the chain of electrical connections. Their importance cannot be overstated, and their potential for future growth is vast. As we look to the future, it is essential that we continue to innovate and develop new technologies that meet the demands of an increasingly complex and interconnected world. By doing so, we can ensure that cat trolley cables remain a critical component in the development of modern electrical systems.

What is the main difference between cat trolley cables and traditional electrical cables?

The main difference is that cat trolley cables are designed to provide a flexible and movable electrical connection, whereas traditional electrical cables are typically fixed in place.

What are some common applications of cat trolley cables?

Cat trolley cables are commonly used in industrial and commercial settings, such as manufacturing, construction, and warehousing, where equipment and machinery need to be frequently moved or repositioned.

How do cat trolley cables ensure safety and reliability?

Cat trolley cables are designed with safety features such as insulation, jacketing, and grounding to prevent electrical shock and ensure reliable operation. They are also subject to rigorous testing and certification to ensure compliance with industry standards.

What are the benefits of using hybrid cat trolley cables?

Hybrid cat trolley cables offer improved performance, increased durability, and enhanced safety features compared to traditional cat trolley cables. They are ideal for use in harsh environments and confined spaces.

How do I choose the right cat trolley cable for my specific application?

To choose the right cat trolley cable, consider factors such as the type of equipment or machinery being used, the environment in which the cable will be used, and the required voltage and ampacity ratings. Consult with a qualified electrical engineer or technician if you are unsure.